| |

Polycrystalline diamond cutter

blanks

(PDC) |

Polycrystalline Diamond Compact (PDC) of Supreme Company is sintered with diamond and WC under ultrahigh pressure and temperature. It integrates the advantages of diamond and WC, with both extremely high wear resistance and excellent shock strength. Polycrystalline Diamond Compact standard specification of Supreme Company is round and other special specifications can be made according to customers’

requirements. Be suitable for manufacturing all kinds of drilling tools, such as oil, geological and engineering drilling bits Polycrystalline Diamond Compact (PDC) of Supreme Company has following three series:

Supreme PDC cutter includes:

1.

Round shape

2.

Sphere shape

3.

Irregular shape which are used to cut various of stone,

for examples, marble, granite, etc.

For Round shape, we have 3

series which are listed as below:

■ SSI Series

SSI Series Polycrystalline Diamond Compact adopts flat tine junction plane. The thickness of diamond layer is about 0.8~1.2mm. It is mainly used in stone processing and hole (blind hole) can be punched according to customers’ requirements.

SSI standard specification

specification |

R1303 |

R1003 |

R0803 |

D(mm) |

13.44 |

10.00 |

8.00 |

G(mm) |

3.53 |

3.53 |

3.53 |

■ SSII Series

SSII Polycrystalline Diamond Compact adopts slotted junction plane. Thickness of diamond layer is about 1.2~1.5mm

SSII standard specification:

| specification |

R1913 |

R1908 |

R1613 |

R1608 |

R1313 |

R1308 |

R1303 |

R1010 |

R0808 |

R0806 |

R0803 |

| D(mm) |

19.05 |

19.05 |

16.00 |

16.00 |

13.44 |

13.44 |

13.44 |

10.00 |

8.00 |

8.00 |

8.00 |

| G(mm) |

13.20 |

8.00 |

13.20 |

8.00 |

13.20 |

8.00 |

3.53 |

10.00 |

8.00 |

6.00 |

3.53 |

■ SSIII Series

SSIII Series Polycrystalline Diamond Compact adopts new net-slotted junction plane, which better removes internal stress of polycrystalline diamond compact; meanwhile the thickness of diamond layer is increased to 2~2.5mm and makes wear resistance much higher.

SSIII standard specification:

| specification |

R1919 |

R1916 |

R1913 |

R1619 |

R1616 |

R1613 |

R1313 |

R1308 |

R1008 |

R0808 |

R0803 |

D(mm) |

19.05 |

19.05 |

16.00 |

16.00 |

16.00 |

16.00 |

13.44 |

13.00 |

10.00 |

8.00 |

8.00 |

G(mm) |

19.00 |

16.31 |

13.20 |

19.00 |

16.31 |

13.20 |

13.20 |

8.00 |

8.00 |

8.00 |

3.53 |

Typical Order Code:

For

Sphere PDC cutter, we make globular

tooth shape and Blunt conical-ended shape now.

Globular tooth shape insert, blunt conical-ended shape insert

Compared with conventional-type Polycrystalline Diamond Compact, it has more excellent shock-resistance toughness (ballistic work is equal to that of hard alloy) and it can be applied to percussion drilling, medium and small drill bit, oil roller bit, down-the-hole drill bit and geothermal drilling etc.

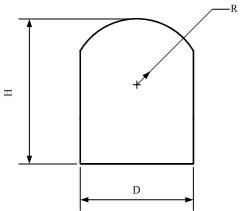

Globular tooth shape insert:

| specification |

Q1114 |

Q1308 |

Q1313 |

|

D(mm) |

11.10±0.1 |

13.44±0.1 |

13.44±0.1 |

H(mm) |

14.30±0.1 |

8.00±0.1 |

13.20±0.1 |

R(mm) |

5.76 |

16.00 |

16.00 |

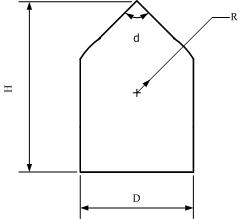

blunt conical-ended shape insert:

| specification |

Z1116 |

Z1119 |

Z1217 |

|

D(mm) |

11.60±0.1 |

11.60±0.1 |

12.10±0.1 |

H(mm) |

16.00±0.1 |

19.10±0.1 |

17.00±0.1 |

R(mm) |

4.00 |

4.20 |

4.50 |

|

d |

60º |

56º |

54º |

For

irregular shape PDC cutter, we

usually cut the PDC according to customers’ requirements, below is our

square shape and triangle shape that we produce at present.

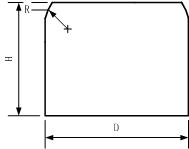

■ Square shape:

Standard specification of square shape PDC cutter:

| specification |

S1208 |

S1205 |

S9408 |

S9403 |

S0808 |

S0803 |

D(mm) |

12.60±0.1 |

12.60±0.1 |

9.40±0.1 |

9.40±0.1 |

8.00±0.1 |

8.00±0.1 |

H(mm) |

8.00±0.1 |

5.60±0.1 |

8.00±0.1 |

3.53±0.1 |

8.00±0.1 |

3.53±0.1 |

R(mm) |

0.8,1.2,1.5,2.0 |

0.8,1.2,1.5,2.0 |

0,0.8,1.2,1.5 |

0,0.8,1.2,1.5 |

0,0.8,1.2,1.5 |

0,0.8,1.2,1.5 |

Chamfer of diamond layer |

0.2±0.1 |

0.2±0.1 |

0.2±0.1 |

0.2±0.1 |

0.2±0.1 |

0.2±0.1 |

Chamfer of WC layer |

0.5±0.1 |

0.5±0.1 |

0.5±0.1 |

0.5±0.1 |

0.5±0.1 |

0.5±0.1 |

Standard specification of triangle shape PDC cutter:

specification |

T1503 |

T1303 |

T1003 |

D(mm) |

15.00±0.1 |

13.50±0.1 |

10.50±0.1 |

G(mm) |

3.53±0.1 |

3.53±0.1 |

3.53±0.1 |

|